Search the whole station

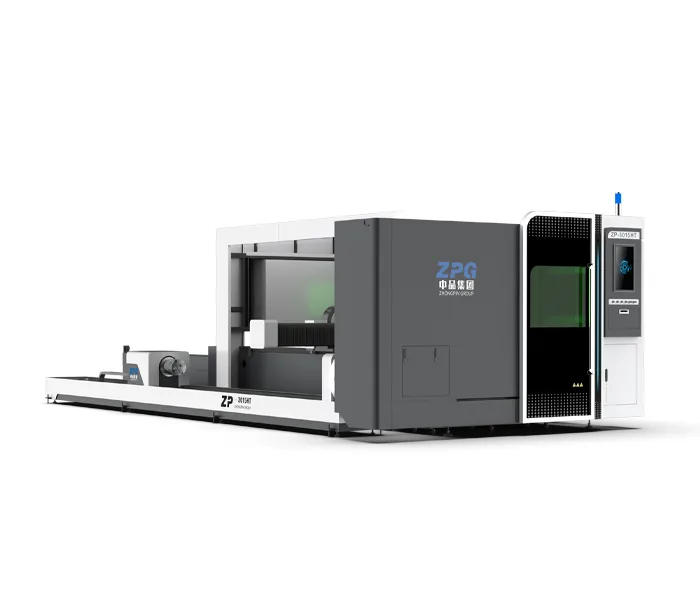

High precision, fast speed, narrow slit, minimum heat affected zone, smooth cut surface and no burr. The laser cutting head does not come into contact with the surface of the material and does not scratch the workpiece. The slit is the narrowest, the heat affected zone is the smallest, the local deformation of the workpiece is very small, and th…

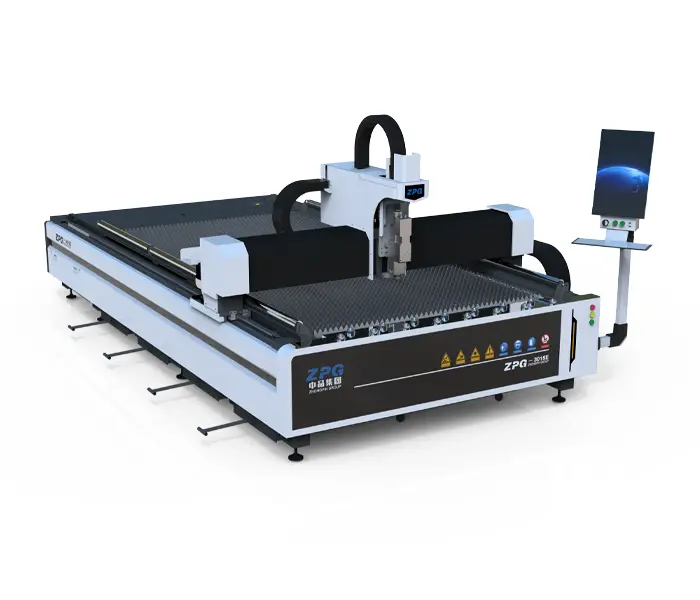

The 3015H CNC fiber laser steel cutting machine uses dual worktables for simultaneous exchange and a fully covered safety protection shell.It is suitable for cutting ultra-large-format medium-thick metal plates, and operates quickly, accurately, and stably in various environments.

The exchange platform structure of A-series fiber laser cutting machine supports double-sided synchronous machining, which can reduce the waiting time and improve the production efficiency by about 50%.

Cutting metal quickly according to computer drawings can be equipped with dust collector, air compressor, automatic feeding manipulator, etc. The high cost performance makes E series metal cutting popular with customers.

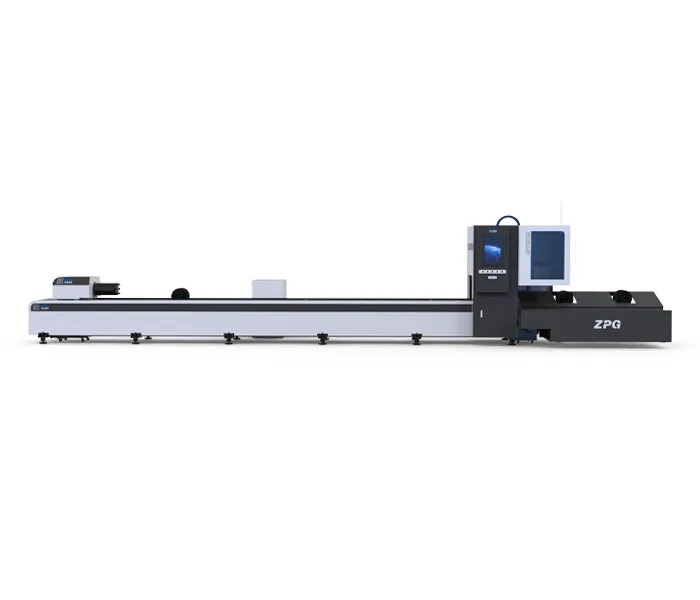

metal pipe laser cutting machine,tube laser cutting machine,steel tube laser cutting machine,metal laser cutting machinefiber laser cutting machine

It can cut various shapes, including holes, grooves and special-shaped cutting, and the cutting quality is good, the incision is smooth and flat, and there is almost no burr, which reduces the need for subsequent processing.

1. The laser pipe cutter adopts numerical control system and high-precision cutting head, which can realize high-precision cutting and the repeated positioning accuracy can reach 0.03 mm.

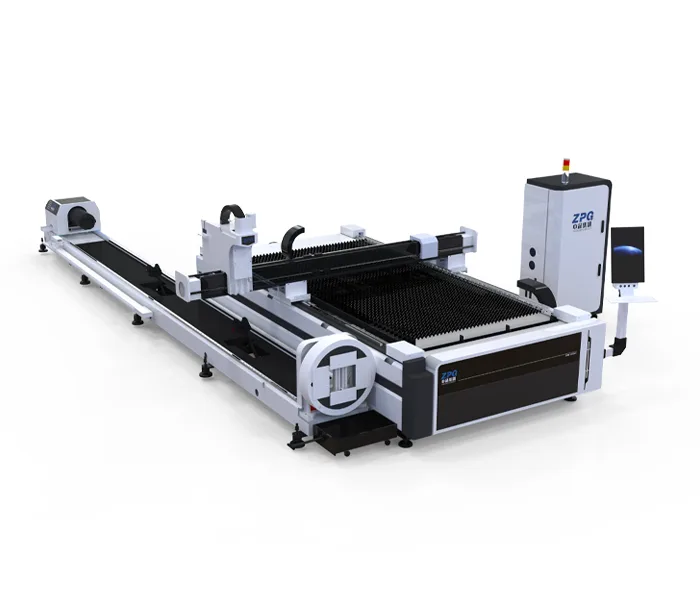

High Precision: High-performance sheet-tube integrated laser cutting machine is suitable for batch metal processing, with fast cutting speed, high precision and stable operation.

3015HT series is a high-performance fiber laser cutting machine, which is suitable for processing all kinds of metal plates and pipes. The full coverage safety protection conforms to the EU CE standard, and the automatic exchange platform can improve the production efficiency by 50%.

Cutting metal quickly according to computer drawings can be equipped with dust collector, air compressor, automatic feeding manipulator, etc. The high cost performance makes E series metal cutting popular with customers.

Submit Inquiry

We will reply to you within 12 hours